See our interview with LG and its advice for solar installers here.

After a Feb. 22 decision approved by the board of directors in South Korea, LG Electronics announced it will exit the global solar panel manufacturing business. The company cited increased material and logistics costs, as well as severe supply constraints, as the main reasons behind the decision to stop solar panel manufacturing.

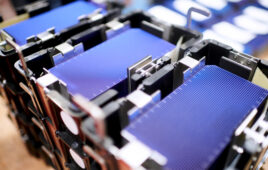

LG will cease production at the 550-MW solar module assembly plant in Huntsville, Alabama, by June 2022. The Alabama plant, which began panel production in 2019, was likely the second-largest crystalline silicon solar panel manufacturing facility in the United States. The company said the 160 employees at the plant and 60 contract workers will be assisted with finding work within LG’s other businesses. The Huntsville campus is also home to LG’s technical call center and service training center.

LG will cease production at the 550-MW solar module assembly plant in Huntsville, Alabama, by June 2022. The Alabama plant, which began panel production in 2019, was likely the second-largest crystalline silicon solar panel manufacturing facility in the United States. The company said the 160 employees at the plant and 60 contract workers will be assisted with finding work within LG’s other businesses. The Huntsville campus is also home to LG’s technical call center and service training center.

LG largely made solar panels for the residential and small-commercial markets. Just this past October, the company launched a new all-black solar panel using “gap-free technology” for an output rating of 405 W.

In the most recent “EnergySage Solar Marketplace Intel Report” (with data covering July 2020 to June 2021), LG was recognized as the third-most quoted solar panel brand in the U.S. residential market, behind only Panasonic and REC. Industry analysts Roth Capital Partners suggest that LG represents 14% of U.S. residential solar module supply.

In the most recent “EnergySage Solar Marketplace Intel Report” (with data covering July 2020 to June 2021), LG was recognized as the third-most quoted solar panel brand in the U.S. residential market, behind only Panasonic and REC. Industry analysts Roth Capital Partners suggest that LG represents 14% of U.S. residential solar module supply.

LG joined other U.S. panel manufacturers this past year, asking the Biden Administration to extend the Section 201 tariffs on imported solar panels. The tariffs were looked at as a way to support U.S. manufacturing by giving U.S. players a fighting chance against cheap imports. Biden did extend the tariffs for four additional years but gave bifacial modules an exemption. Although bifacial modules are primarily used in utility-scale projects, their exemption from the tariff means they could still come into the United States cheaper than traditional panels produced domestically for the residential market, thereby putting local residential suppliers at a disadvantage. Chatter on social media suggests this may be another reason behind LG’s decision to exit the panel manufacturing business.

Although panel production is ending, LG said it will continue to support its U.S. solar customers and honor the limited warranty with each product sold. Going forward, LG will shift its focus to the “new era of sustainability” through energy storage systems and home energy management.

“While exiting the solar panel business, LG is concentrating on products and services that can have an even greater impact,” said Thomas Yoon, president and CEO of LG Electronics North America, in a press release. “Sustainability is a core business principle at LG Electronics, and we are constantly evaluating the ways in which LG can unlock potential, create greater value and support our vision for a better life for all.”

Thanks Kelly – was wondering what was going on with LG. John – on solar PV tariffs, Obama did it on a company selective basis under the premise of anti-dumping; Trump did it as part of his campaign for coal, then to protect a non-existent U.S. manufacturing industry (assembly only, show me one mine to ingot, to cell, to module operation in the U.S. – all assembled mostly Chinese components), then landed on general tariffs against China; and Biden is on the same misinformed path as trump about protectionism but finally figured out the is trans-shipment of modules and components and some Chinese owned manufacturing throughout the Asian rim to avoid tariffs. Sure, Mercury, the U.S. has some of the raw materials, but we also have significantly more environmental and land use laws (mostly thankfully), and significantly higher cost of energy and cost of labor. We simply cannot compete on a cost effective or economy of scale basis. Same thing for junk like Tupperware and 90% of the stuff in Walmart. Kelly, if you know something different, please let me know. PV mods assembled here and manufactured elsewhere can be considered American under former ARRA and for gov’t procurement under the doctrine of substantial transformation under the Buy America Act, with 51% of the product value coming from U.S. labor/assembly. Richard – right, been in solar for 15+ years – 40-50% of installed system cost is design, permitting, labor, and profit margin. John, it is not a Dem/Rep issue. It is an issue of bi-ignorance in leadership. but you are right, cost effective solar and renewable energy products in general, along with the slow, but eventual modernization of our electric grid, that was conceived in the Eisenhower era, started getting built and connected around Nixon era – which is still fundamentally based on 100 year old technology – represents a massive new industry and employment opportunities of other U.S. based manufacturers, suppliers, SMBs, electrical workers including IBEW, engineers, IT, and capital providers.

Sorry John,

These tariffs have not prevented one project from getting done. Panels are CHEAP. Panels are plentiful. Cost is in the labor, BOS, time of permits, etc… Maybe some enterprising company will buy the factory?

John is on the money. but I am pretty sure these oriental manufacturers use really cheap labor (slaves/prisoners?) and have not regard for contamination of the global enviornment.

Jim Johnson

This is unfortunate for the workers .But this could be a perfect opportunity for us to get into this space and create a made in USA solar manufacturing.

This is a great article Kelly and a really important point in the argument against tariffs. So, these guys push for extension of the section 201 tariff, then pull out of the business entirely two months later. The dems just can’t shoot straight on this stuff. They are so beholden to the perceived political powers of their labor constituents they miss the bigger picture: growing solar deployments is the best way to increase high wage jobs. Developers hire a lot more IBEW men and women than these tiny mfg concerns.