I don’t like the phrase “state-of-the-art.” It’s overused and often misrepresents basic facility upgrades.

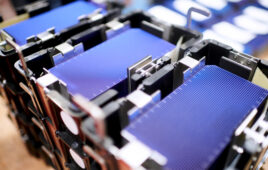

But JinkoSolar‘s new 400-MW solar panel assembly plant in Jacksonville, Florida? This is a state-of-the-art solar manufacturing site, in the truest sense. I’ve had the opportunity to tour multiple solar manufacturing facilities in the United States, and never have I seen a place more organized and automated than Jinko’s new site that will produce both 60- and 72-cell mono PERC modules.

But JinkoSolar‘s new 400-MW solar panel assembly plant in Jacksonville, Florida? This is a state-of-the-art solar manufacturing site, in the truest sense. I’ve had the opportunity to tour multiple solar manufacturing facilities in the United States, and never have I seen a place more organized and automated than Jinko’s new site that will produce both 60- and 72-cell mono PERC modules.

The facility, which began a pilot line in November 2018 and officially held a ribbon cutting yesterday, is not yet at full capacity. Officials promise the plant will bring 200 jobs to Jacksonville, and almost 150 employees have been hired thus far. Once completely operational, the $50.5 million facility will produce two panels per minute, 24/7 — over 1 million panels per year. It is a feat in U.S. manufacturing that was exciting to see first-hand. Here are a few things I learned after touring the plant during its official grand opening.

This is the most advanced JinkoSolar plant in the world.

This is the most advanced JinkoSolar plant in the world.

JinkoSolar has been the largest solar panel manufacturer globally for the last three years, selling in 108 countries. The company primarily manufactures 6.5 GW of solar cells and 10 GW of modules out of its core Chinese and Malaysian plants, but officials said now 400 MW of modules will come out of Jinko’s most advanced facility yet in Florida. Soldering is completely automated. Robots place and attach junction boxes. Artificial intelligence is used to find any microcracks in modules before they’re laminated. Machines sort and box modules for shipment. The new facility is as cutting-edge as solar panel manufacturing can be in 2019.

The 400-MW plant won’t come close to meeting U.S. demand for Jinko product.

The 400-MW plant won’t come close to meeting U.S. demand for Jinko product.

Over 40 GW of Jinko panels have been deployed globally, with 6 GW installed in the United States — a number that is quickly growing. JinkoSolar’s U.S. sales have grown 250% since 2013, now well exceeding the 400 MW that will eventually come out of the Jacksonville plant annually. Although the facility will produce modules for both the residential and utility markets, the Florida plant may be busy fulfilling a 2.75-GW supply deal with NextEra Energy for use in Florida Power & Light projects. U.S. demand for the tier 1 manufacturer will still have to be met with imported (and tariffed) solar panels.

Florida is now a hub for sophisticated solar panel designs.

Florida is now a hub for sophisticated solar panel designs.

Not only is the U.S. JinkoSolar facility producing five-busbar mono PERC modules (advanced just by themselves), Nigel Cockroft, general manager of JinkoSolar (U.S.), said the lines will soon be producing half-cell panels and possibly bifacial modules in the future. All panels coming out of Jacksonville will feature DuPont Tedlar backsheets, the most tested and trusted polymer backsheets on the market. JinkoSolar also just announced it has signed on as one of the first panel companies to use DuPont’s clear backsheet for bifacial modules — which may be manufactured in Florida.

This brings a unique opportunity to Jacksonville and northern Florida. Not necessarily known as a technology hub, the area will soon support 200 direct and nearly 600 indirect jobs from JinkoSolar’s advanced manufacturing processes. Other big panel manufacturing facilities are scheduled to come online this year (LG in Alabama and Hanwha Q CELLS in Georgia), but JinkoSolar has set the bar pretty high for solar panel manufacturing in the United States.

Where can we buy these US manufactured panels in the US?

Check with your local distributor.

Nice work Kelly!

You are my trusted source of information for solar industry

David Bewernitz

3D Solar – Odessa, FL

Thank you! 🙂