That depends on what type of solar panel you’re looking at. There are two main types of solar panels, or modules, used in rooftop and ground-mounted installations: crystalline silicon and thin-film.

Crystalline Silicon Solar Panels

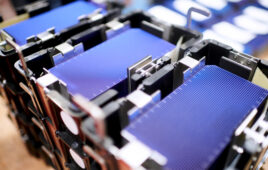

Crystalline silicon (c-Si) solar panels are the most common. They’re the ones that look like blue or black rectangular grids of smaller squares. Those smaller squares are silicon solar cells, and they link together in a series to form a circuit. The more interconnected cells in a series, the more electricity produced by the system.

Crystalline panels are more commonly grouped in 60-cell and 72-cell panels. Smaller panels are also used in the off-grid market. These series of cells are connected together usually by busbars. Busbar ribbons (typically made of aluminum or copper with silver) wire solar cells together to create higher voltages. The more busbars across a solar cell, the more electrons generated that can pass through, and power and efficiency of the solar panel increases.

There are two core types of crystalline silicon designs: polycrystalline and monocrystalline. Monocrystalline silicon solar is made by growing a single crystal. Because these crystals are usually an oval shape, monocrystalline panels are cut into the distinctive patterns that give them their recognizable appearance: the sliced silicon cells expose the missing corners in the grid-like structure. The crystal framework in a monocrystalline is even, producing a steady blue color and no grain marks, giving it the best purity and highest efficiency levels.

Polycrystalline solar is made by pouring molten silicon into a cast. However, because of this construction method, the crystal structure will form imperfectly, creating boundaries where the crystal formation breaks. This gives the polycrystalline silicon its distinctive, grainy appearance, as the gemstone type pattern highlights the boundaries in the crystal. These impurities in the crystal makes polycrystalline modules less efficient and also cheaper than monocrystalline.

Thin-Film Solar Panels

Thin-film panels are more traditionally used in large utility-scale installations. A thin semiconductor is deposited on glass, plastic or metal foil substrates. Thin-film, by its name, can be very thin and sometimes flexible. Its light weight and flexibility has led to its use on curved roofs, automobiles and other unique installations.

There are three common thin-film divisions: amorphous silicon (a-Si), cadmium telluride (CdTe), and copper indium gallium selenide (CIGS). Thin-film solar cells are often created through a co-evaporation process of chemicals on a glass sheet. They have lower conversion efficiencies than silicon, but reduce the amount of material required in creating the cell.

Module Assembly

In general, all solar panels consist of solar cells with a glass layer on front and a protective backsheet on the rear. Usually made from a type of polymer, backsheets adhere to the backside of modules to provide electrical insulation. White backsheets are most common, although more black backsheets are being used on high-efficiency modules looking for a certain aesthetic.

Aluminum frames usually finish a module. They add strength to the panel and protect the edge of the glass. The frame helps racking and mounting systems attach to the panel to secure it to the roof or ground.

But all of this is changing. With new bifacial designs (when solar cells are exposed on both the front and back sides of the panel), backsheets are no longer needed. Some panels are also going frameless, choosing to either sandwich solar cells between two pieces of glass or using sturdier backsheets that don’t warrant a frame.

This article was compiled from information in previous Solar Power World articles:

- What are solar panels made of?

- What are the different types of solar modules?

- How does thin-film solar work?

- Busbars: A solar panel necessity or hindrance?

- CIGS thin-film: Solar’s black sheep is finding its feet

- Are backsheets ruining solar panels?

- What are bifacial solar modules?

- The 411 on frameless solar modules

See where popular brands of solar panels are manufactured and assembled.

Thanks Kelly! I’ve been in solar for 18 months and finally understand what solar panels are made of. Kinda embarrassing for an executive. Keep up the great work!