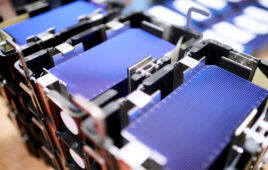

Crossroads Solar employees at work.

By Patrick Regan, president, Crossroads Solar

The climate provisions in the Inflation Reduction Act open up a window on what could be. Inside that window is a model for rethinking and revolutionizing the way we manufacture solar modules in America.

Crossroads Solar has demonstrated that you can build a solar module production facility from the ground up, in the United States, in the 2020s and with a labor force comprised of men and women who traditionally struggle to find good employment. All of Crossroads’ employees are felons reintegrating into society.

Crossroads is a manufacturing facility producing fully UL-certified solar modules in a 12-MW annual production capacity facility. Our panels are sold regionally to the install community and nationally through Krannich Solar, and are used on houses, farms and commercial buildings throughout the upper Midwest. We have, so far, sold every module that we have produced and have a backorder of sales.

The uniqueness of Crossroads is not only that we are a U.S.-made module manufacturer that started from the ground-up in 2021, or that we have a workforce comprised only of second-chance citizens, but rather in the potential for our model of production to revolutionize the solar industry in this country.

The contemporary model is comprised almost exclusively of gigawatt-sized production facilities that are highly automated, mostly foreign-owned subsidiaries of billion-dollar companies that employ a labor force that is highly skilled, highly educated and mostly executive-level. But Crossroads demonstrates that it doesn’t need to be that way; we do not have to organize solar manufacturing around the highly automated, highly corporate structure.

It would take 25 Crossroads-sized facilities scaled to 40 MW in annual production each to equal the output of one gigawatt-sized factory. At first blush, and maybe to the local MBA graduate, this would seem inefficient. But imagine a 40-MW facility sited on tribal lands and employing people from the community that have traditionally struggled to find meaningful and well-paid jobs, or in a former coal mining community where the jobs have been displaced by the need to wean ourselves from a reliance on coal. A facility like Crossroads that is scaled to produce in the 40-MW range would provide jobs and skills for those on the labor side of our economic engine. Instead of a front office fleshed out with engineers and accountants, presidents and vice presidents, we could have 25 men and women working on the floor producing panels, with relatively few in the executive suite. This is what the Crossroads model has demonstrated as an alternative pathway to successful solar panel manufacturing.

So imagine those 25 smaller-scale production facilities dispersed across Native lands, former coal mining communities and inner cities, each producing panels for an expanding solar industry. Crossroads Solar has hired men and women who have served from years to decades in prison, often without skills or, in a few cases, knowledge of computers or cell phones. We have trained them to produce quality panels and to be committed to the experiment that we call Crossroads. The customers who purchase the Crossroads panels are thrilled to be able to offer a truly American-made product, and their clients are equally thrilled to be able to support American-made panels and the social mission that underscores the Crossroads project.

So imagine those 25 smaller-scale production facilities dispersed across Native lands, former coal mining communities and inner cities, each producing panels for an expanding solar industry. Crossroads Solar has hired men and women who have served from years to decades in prison, often without skills or, in a few cases, knowledge of computers or cell phones. We have trained them to produce quality panels and to be committed to the experiment that we call Crossroads. The customers who purchase the Crossroads panels are thrilled to be able to offer a truly American-made product, and their clients are equally thrilled to be able to support American-made panels and the social mission that underscores the Crossroads project.

Crossroads is a for-profit company. The margins are tight, the pay structure is flat and the enthusiasm is high. This model could be transported across the country.

An initial concern might be that 25 individual panel manufacturers would be competing with each other, but I don’t think that is the right focus. Most of the Crossroads market is regional, maybe even local. Yes, Krannich markets our panels nationally, but our regional business flourishes. Intelligently dispersed across the country, these 25 facilities would be cooperative, not competing. One in Virginia, one in West Virginia, one in Kentucky. With the increase in demand for solar power that will result from the recent climate legislation, each of these facilities would find adequate local markets to keep out of each other’s way.

Moreover, 25 independent production facilities would be able to cooperate on the purchasing side of the ledger. Crossroads struggles not at figuring out how to be competitive at a smaller scale, but in trying to determine how to navigate the supply chain at this scale in a world where suppliers give preference to the huge market over the small. If buying power could be aggregated — in effect, a buying cooperative — these smaller-scaled facilities would not face price point pressures that most assume would make them less competitive. Buy cooperatively, sell independently and hire and train locally is a prescription for success that even some of the gigawatt producers could not navigate. For example, LG closed its doors to solar manufacturing because it could not find a way to be competitive in this tight market. Scale may have worked against it.

I refer to this as a distributed solar production model, and I have had conversations with people from Alaska to Louisiana about developing a production facility in their local communities. What Crossroads brings to the table is the knowledge base on how to start from scratch, an understanding of production processes and efficiencies, and under the right conditions, Crossroads can also offer a shortened runway through the certification process. Combined with economies of scale in purchasing raw materials, the distributed model would provide for increased access to solar modules by local installers who often struggle to buy from the large producers. If you are forced to purchase at container-quantities to secure competitive pricing from large manufacturers, smaller installers confront the choice of either being less competitive in their market or tying up their cash and constraining cash flow. Small-scale production like Crossroads allows us to sell at the pallet or the truck load because size makes us nimble. A distributed production approach would increase access to the smaller installer community and therefore increase access to the individual trying to find a way to go solar as they take advantage of solar incentives.

I refer to this as a distributed solar production model, and I have had conversations with people from Alaska to Louisiana about developing a production facility in their local communities. What Crossroads brings to the table is the knowledge base on how to start from scratch, an understanding of production processes and efficiencies, and under the right conditions, Crossroads can also offer a shortened runway through the certification process. Combined with economies of scale in purchasing raw materials, the distributed model would provide for increased access to solar modules by local installers who often struggle to buy from the large producers. If you are forced to purchase at container-quantities to secure competitive pricing from large manufacturers, smaller installers confront the choice of either being less competitive in their market or tying up their cash and constraining cash flow. Small-scale production like Crossroads allows us to sell at the pallet or the truck load because size makes us nimble. A distributed production approach would increase access to the smaller installer community and therefore increase access to the individual trying to find a way to go solar as they take advantage of solar incentives.

Scale is important. Here at Crossroads, our initial project has demonstrated that we are a little bit too small. But the climate provisions in the IRA help provide the resources for smaller groups to initiate the development of a scaled production of solar in their community. The manufacturing credits reduce the risk and make much, much, easier the private partnerships required to make a distributed model work. And investments by state and local governments that see the value of targeted employment around solar production can also help incentivize creative financing by private interests. These would be well-paying jobs with benefits that require skills that can be taught, and can revitalize a local workforce.

It is hard to overstate the value of the IRA climate provisions in providing the opportunity to rethink how we consider the efficiencies of solar production in America. It will take coordination, foresight and some community involvement, but there is a model on the table to provide for climate relief and workforce development at scales that can revolutionize solar module production in the United States.

Patrick Regan is a former professor of political science at the University of Notre Dame and Binghamton University. In 2019, he resigned his position at Notre Dame to co-start Crossroads Solar. Today, he is a full time manufacturer of solar panels, and in the process developing a model to revolutionize the way we manufacture panels in the U.S. and the way we think about workforce development.

Patrick Regan is a former professor of political science at the University of Notre Dame and Binghamton University. In 2019, he resigned his position at Notre Dame to co-start Crossroads Solar. Today, he is a full time manufacturer of solar panels, and in the process developing a model to revolutionize the way we manufacture panels in the U.S. and the way we think about workforce development.

Great article!

How could I get Mr. Regan and company to build a solar panel facility in Reeves county, west Texas to employ felons and disabled Vietnam

veterans like me who cannot get a job in the area? Shipping is easy from here, Interstate Highways 10 and 20 pass through this area

and there is a willing workforce. I have a degree in electrical engineering and electronics, 50 years in the oil and gas industry in the area,

and 7 years with Texas Instruments LMOS semiconductor fabrication plant while the oil and gas industry was depressed from 1986 to 1993.

Land is relatively cheap in this area $1500 to $2500 per acre. Plenty of electricity service and water. Plenty of steel building construction

firms in the area hungry for construction jobs.

Please contact me. westtxlawrence@aol.com

I would like to converse with Mr. Reagan about developing such a facility like this,

in the Baltimore Metropolitan Area.

Respectfully requested,

Derrick A. Burnett

President / CEO

AEI-Design Build LLC.

http://www.aeidesignbuild.net

(443) 985-0742

You can reach him at patrickregan@crossroads-solar.com